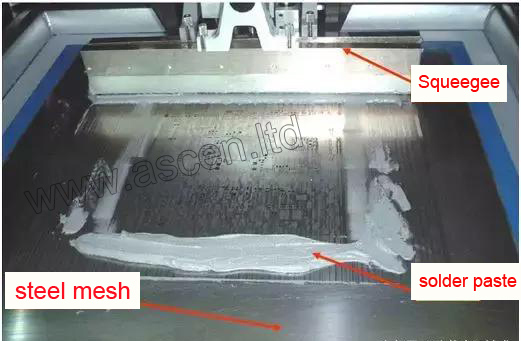

Soldering paste is one of the first steps in the SMT assembly process,Soldering paste is “printed” on the boards using the silk-screen method. That is why we said this machine is the PCB solder paste printer. Depending on the design of the board, different stainless-steel stencils for “printing” the paste onto the board and various product-specific pastes are used. After the soldering paste is on the boards, a 2D-soldering paste inspection is performed to ensure that the paste is evenly and correctly applied. Once the accuracy of the soldering paste application has been confirmed, the boards are transferred to the SMT assembly line, where the components will be soldered.

When finish the PCB soldering, the PCB board like the following:

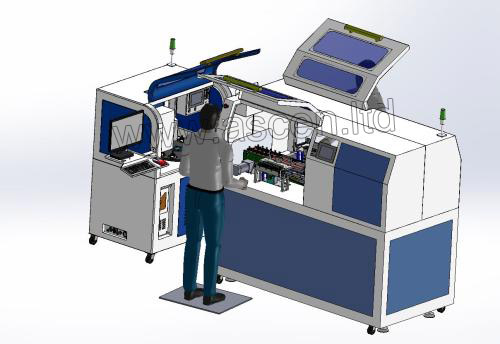

There are two options for printing presses: manual PCB solder paste printer and fully automatic solder paste printer, manual PCB solder paste printer cannot be connected to other SMT devices and requires human intervention (such as the transfer board).automatic PCB solder paste printer with high degree of automation and high efficiency is suitable for large-scale production.

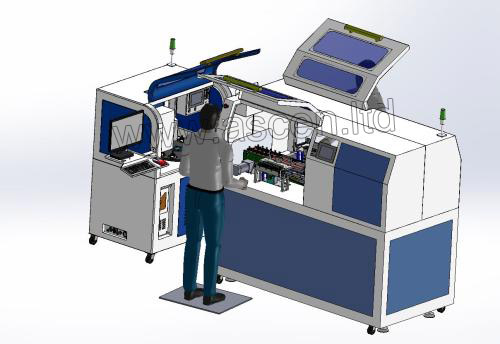

Component placement and assembly processing

Please refer the station 5 on the whole SMT electronic production line

The SMT pick and place machine is the primary core equipment, which used to achieve high speed, high precision, automatic placement components, related to the efficiency and accuracy of SMT assembly production line, it is the most critical and complex equipment, most of the the large and medium-sized manufacturer, their SMT assembly line include 2 units of SMT pick and place machine to keep the demand, the Chip mounter and IC mounter, or you can only choose one multi-function placement machine, the multi-function placement machine can complete all components mount, reduce investment, more suitable for small and medium-sized enterprises investment.

Please refer the station 6 on the whole SMT electronic production line

To solder electronic components, we use two different methods, each of which has distinct advantages depending on the order quantity. For series production orders, the Reflow-soldering process is used via the reflow oven. During this process, boards are put in a nitrogen atmosphere and are gradually warmed up with heated air until the soldering paste melts and the flux vaporizes, which fuses the components to the PCB. After this stage, the boards are cooled off. As the tin in the soldering paste hardens, the components become permanently affixed to the board and the SMT assembly process is completed.

For prototypes or highly sensitive components, we have a specialized vapor-phase soldering process. In this process, boards are heated until the specific melting point (Galden) of the soldering paste is reached. This allows us to solder at lower temperatures or solder different SMT components at different temperatures depending on their individual soldering temperature profiles.

After the PCB soldering process by the reflow oven,the PCB board like the following:

Now our reflow soldering equipment is developing towards high efficiency, multi-function, intelligent, one has a unique more nozzle airflow control of reflow oven, reflow oven with nitrogen protection, reflow oven with local forced cooling components can monitor temperature of reflow furnace, the reflow oven with dual conveyer belt center support device of reflow furnace, etc.

In addition to these new reflow oven, in order to connect the new intelligent production line,we start to research and development the intelligent reflow oven, this type reflow oven adjusting operation is controlled by a built-in computer, in a window Windows operating environment can be very easy to use keyboard or light pen input all kinds of data, and can be quickly removed from memory or replace reflow soldering process curve, save the adjusting time, further improves the production efficiency ,

the above 3 step process, total include the PCB solder paste printer, PCB pick and place machine and reflow oven, the performance and efficiency of a production line depend on these three type process equipment.

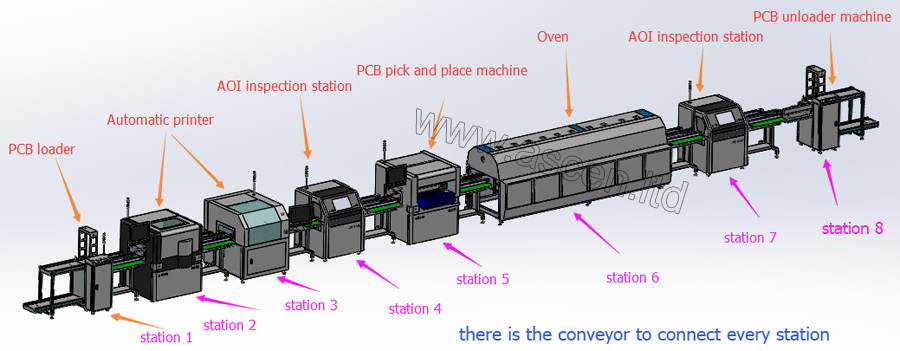

Except that, the whole SMT electronic intelligent production line still include the PCB handing system and the AOI or SPI visual inspection system for keep the high production quality and high production output.

PCB handing system include the PCB conveyor, PCB loader/unloader, PCB inverter,PCB destacker, PCB turn conveyor and include the all equipment for helping transfer the PCB board on the SMT electronic production line. We need select different PCB handing system according to the function of production line. Please refer the PCB loader of station 1 , PCB unloader of station 8 on the whole SMT electronic production line, include the PCB conveyor between in every equipment, PCB loader as the first machine on the line, it use for loading the PCB board into the whole line , and the PCB unloader in the end for unloading the PCB board into the magazine rack. These machine is an indispensable part of the SMT intelligent production line.