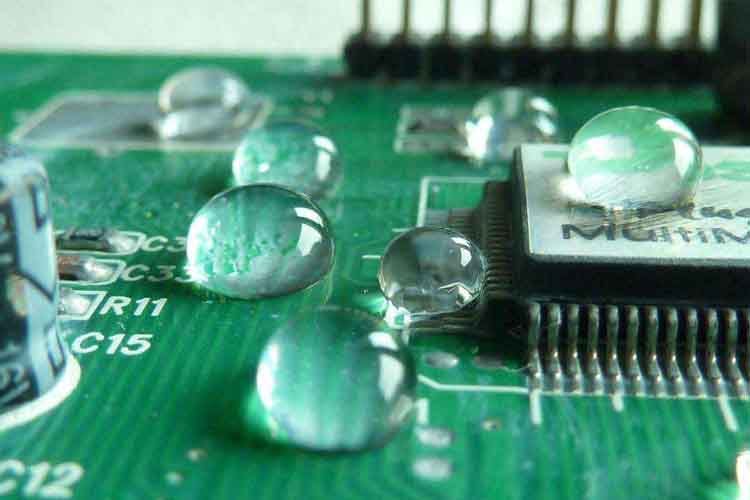

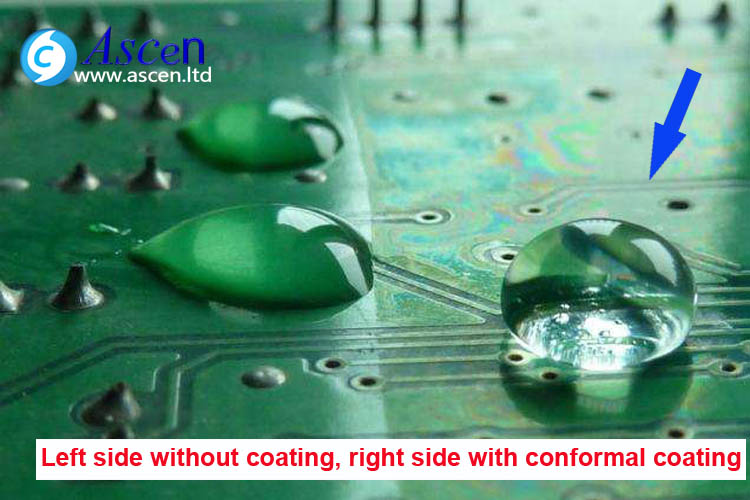

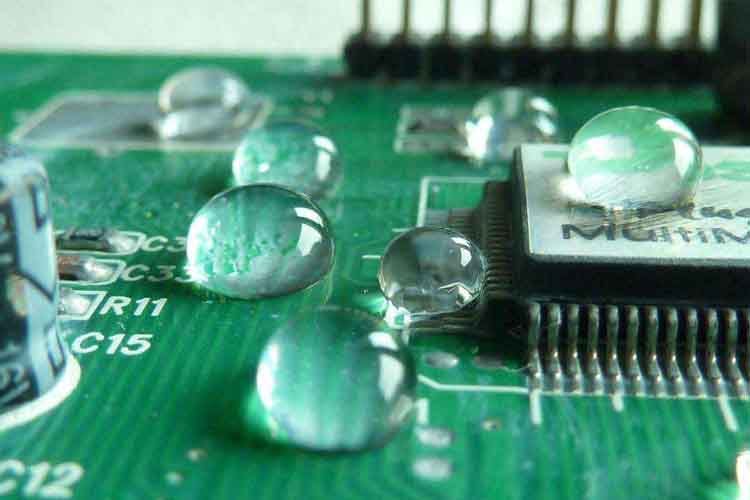

Conformal coating is a protective coating or polymer film 25-75µm thick (50µm typical) that ‘conforms’ to the circuit board topology. Its purpose is to protect electronic circuits from harsh environments that may contain high humidity, a range of airborne contaminants and varying temperatures. By being electrically insulating, it maintains long-term surface insulation resistance (SIR) levels and thus ensures the operational integrity of the assembly. It also provides a barrier to air-borne contaminants from the operating environment, such as salt-spray, thus preventing corrosion.

Conformal coatings are a breathable protective layer that will protect against the particular environment the PCA is exposed to by filtering out the airborne contaminants and maintaining long-term surface insulation resistance but will also allow any moisture trapped in the circuit board to escape.

The concept of a conformal coating of electronics was originally proposed,after the conformal coating machine application more and more popular, and through research to meet the demanding requirements of PCB conformal coating.ASCEN was the part of ASCEN early research and has remained a pioneer as the PCB conformal coating machine technology has expanded to an array of industries today including:

Aerospace

Automotive, including Hybrid and EV

Industrial Controls

White Goods

Telecoms

Energy both Traditional and Renewable

Learn more combined solution about PCB conformal coating (click here) or contact us for assistance determining which circuit board coating process would work best for your application.

Which industry requires Conformal Coating machine?

The use of conformal coating machine is particularly important in automotive, military, aerospace, marine, lighting, industrial and green energy applications. However due to the rapid expansion of the electronics industry, conformal coatings machine are also finding their way into the domestic and mobile electronics industries, providing the necessary combination of high performance and reliability within a vast array of electronic devices.

What Are The Advantages Of Using A Conformal Coating for PCB?

Insulating properties can allow a reduction in PCB conductor spacing

Can help eliminate the need for complex, sophisticated enclosures

Provide extended service life by:

PCB conformal coating protecting against humidity, chemical, and physical attack

PCB conformal coating protecting against thermal variations and shocks

PCB conformal coating protecting against vibration and mechanical shocks

How To You Apply Conformal Coating?

How a conformal coating is applied is dependent mainly upon:

PCB conformal coating application method

Existing Available Equipment (conformal coating spray equipment, curing equipment etc..)

Board Design/Complexity/Masking Needs

Desired volumes/cycle times.

Methods Of Conformal coating application: (In Order Of Sophistication)

|

|

Advantage |

Disadvantages |

|

Manual Brush Coating |

Low capital cost |

Labor intensive inconsistent/poor quality slow/low volume |

|

DIP Coating |

Moderate/High volume, Fairly consistent coating |

Limited coating choices due to pot life issues,Large masking requirement |

|

Manual Spray coating |

Low capital cost, Moderate volume,Light masking required |

Operator dependent |

|

Selective Automated Spray |

Highest productivity/volume,Most consistent results,Minimizes masking efficient, Only cost where needed |

Capital cost |

Methods Of Drying And/Or UV Curing Conformal Coatings?

With all four PCB conformal coating application methods noted above, it will also be necessary to dry and in some cases cure or crosslink the applied coating. Not all methods will be applicable or possible for all chemistries, for example UV curing coatings can only be cured with UV curing equipment.

|

|

Advantages |

Disadvantages |

|

Air dry |

Low investment |

Slow inconsistent/Environment Dependent |

|

Oven Dry(batch or continuous) |

Moderate Investment Higher Volume possible |

Investment |

|

UV light cure |

Very Fast and very consistent |

Capital Cost,Shadow Areas |