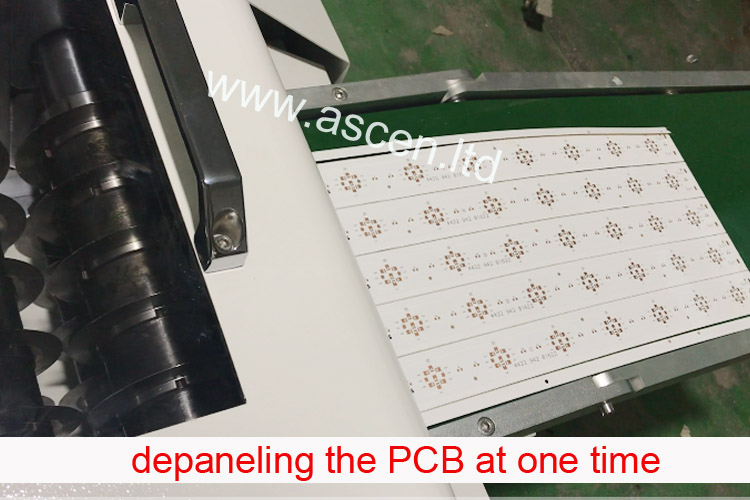

This PCB depaneling machine 900 model with the multi blade, It can depaneling the whole PCB/LED board simultaneously without deformation and burrs, it is very popular to suitable for separate the large quantities of milled PCBs on the PCB assembly line.Most of lighting manufacturer which in the mess production will choose this multi cutter type PCB depaneling machine to reduce their labor cost , and then save their more production cost.

If you are the LED light manufacturer, Your can choose this machine cutting the T8 tube strip or PCB panel which in the FR4/Aluminum/CEM-1 material. most of LED panel with multi PCB stripes, the operator need separate up to 20 PCBs in every PCB panel, multi cutter type PCB depaneling machine use for your PCB panel only need 5 second to finish, and only need one operator to finish, that is greatly for save the time and with the high efficiency, if your factory in the mess production, this 900 model is the best way to save our more production cost.

To compare the single cutter type PCB depaneling machine, Please check the ASC-700N series PCB cutting machine, this PCB cutting machine only cut the PCB board one by one. mutli cutter PCB depaneling machine have the higher precision and higher efficiency than ASC-700N series machine, single cutting type ASC-700N series machine cut the PCB one by one, and the multi cutter type 900 machine can cut the whole PCB at one time. you can compare this both machine like following:

If your PCB has 10 V-cut, the production efficiency for one set 900 machine = 10 sets of 710 machine simultaneous operation. add 10 workers cost, but the ASC-900 machine only need one operator labor cost, so the multi cutter type PCB depaneling machine will save your more cost in the future.

Of course, if your factory with the low output, ASC-700N series PCB cutting machine is best choose for you.