By the way,if your company need more efficient PCB depaneling router machine,you can click video link here double station PCB router machine to check the large scale PCB router depaneling machine how to quickly connect the robot.

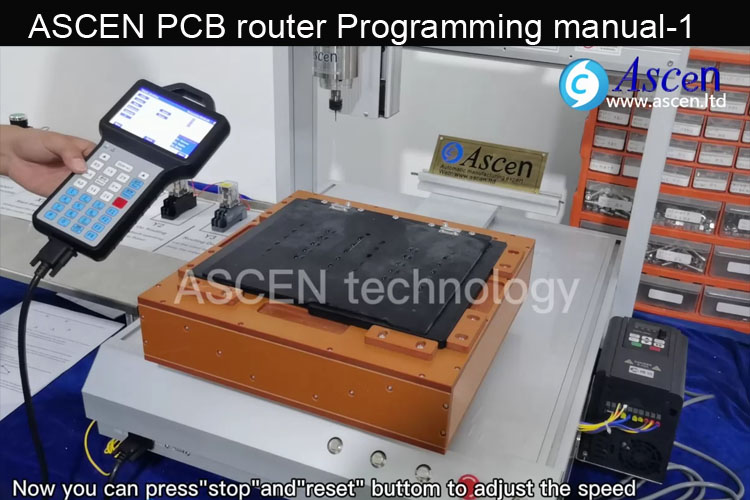

ASCEN PCB router depaneling machine AS-3A/4A model,the programming manual total 1-9 part.please check the following link to see the detail:

PCB depaneling router manual part 1, learn PCB router machine function and the operation interface

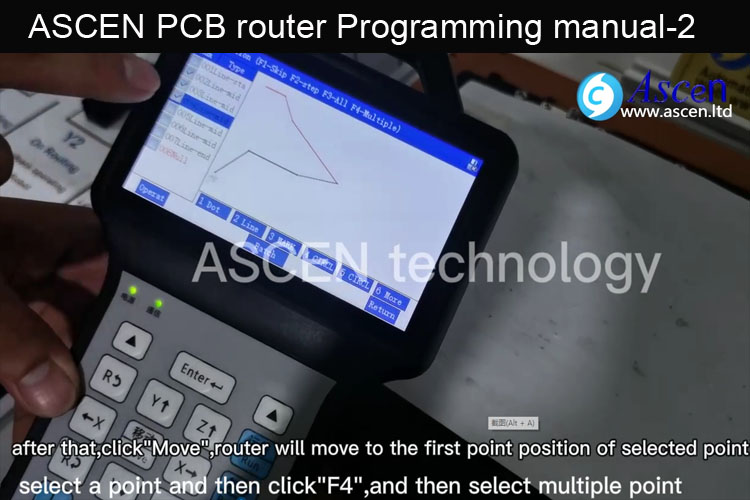

PCB depaneling router manual part 2, learn PCB router machine "Move and edit"function

PCB depaneling router manual part 3, learn PCB router machine "Insert instruction"

PCB depaneling router manual part 4, learn PCB router machine "copy instruction"

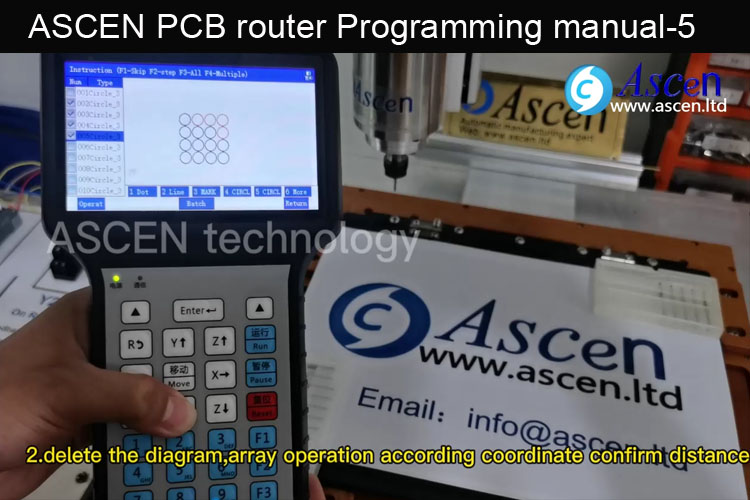

PCB depaneling router manual part 5, learn PCB router machine "Array replication"function and offset operation

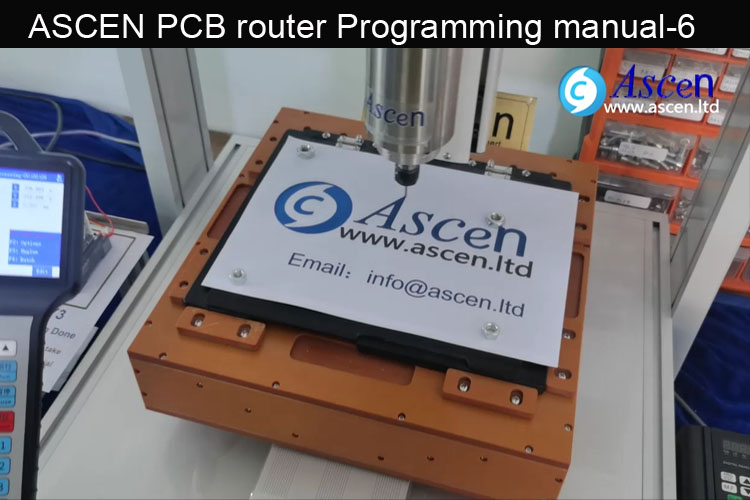

PCB depaneling router manual part 6, learn PCB router machine modify parameters

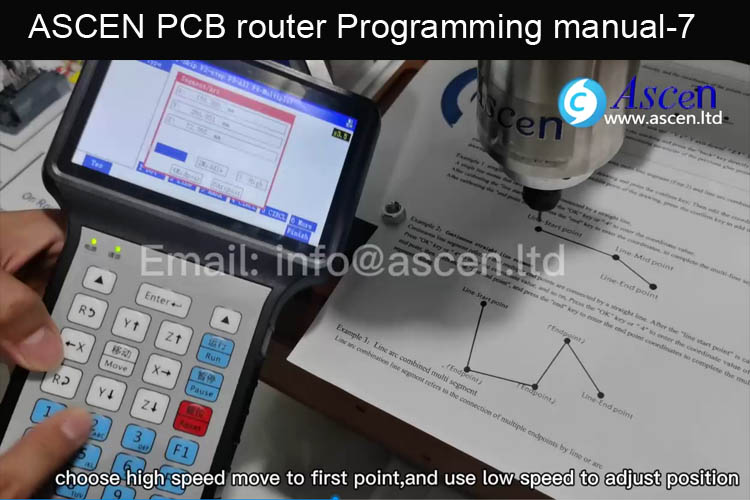

PCB depaneling router manual part 7, learn PCB router machine "Dot" and "Line"instruction

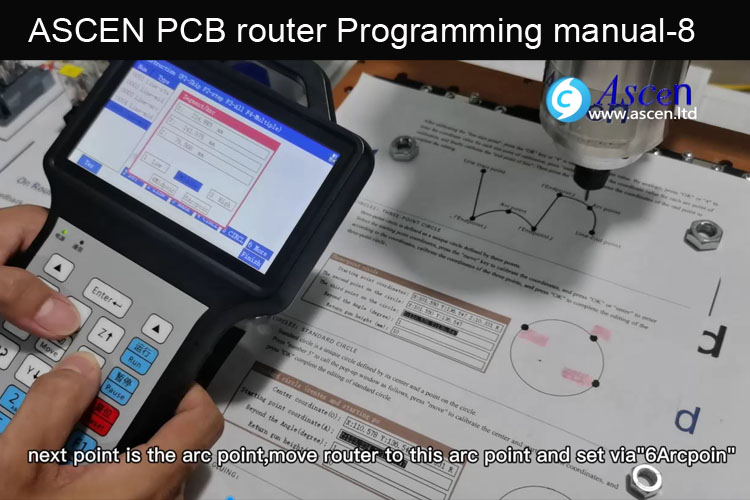

PCB depaneling router manual part 8, learn PCB router machine “Line arc combined multi segment” instruction

PCB depaneling router manual part 9, learn PCB router machine drawing diagram via PCB panel