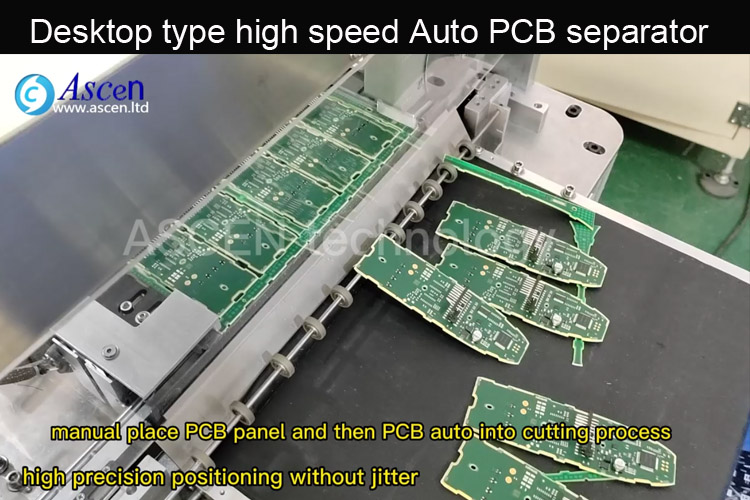

1)Machine internal stress of splitting is less than 500 strain.

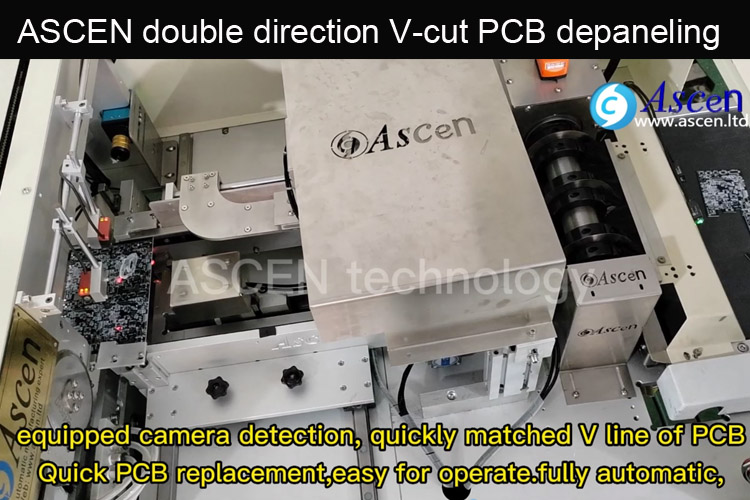

4)Machine suitable for cutting the V-slot side nearest distance from component is 0.2mm in circuit board

5)Blade material: import Japanese high-speed steel via precision grinding

| Item | Scope of application |

| Model number | ASC-620 |

| Dimensions(L*W*H) | 700*550*460mm |

| PCB Board thickness | 0.2-4mm |

| Maximum PCB board length | 340mm |

| Maximum cutting width | Unlimited |

| maximum allow component height on top | 40mm |

| maximum allow component height on bottom | 24mm |

| Working temperature | 10-35 degree |

| Power Supply | 1P AC220V 50Hz or 110V/60Hz |

| Weight | Approx.252Kg |

If you want to know more different PCB depaneling machine for different type PCB panel,Please click here PCB depaneling equipment list

If you feel irresolute for choose the PCB depaneling machine, Please click here: Choose the PCB depaneling machine quickly separate PCB panel