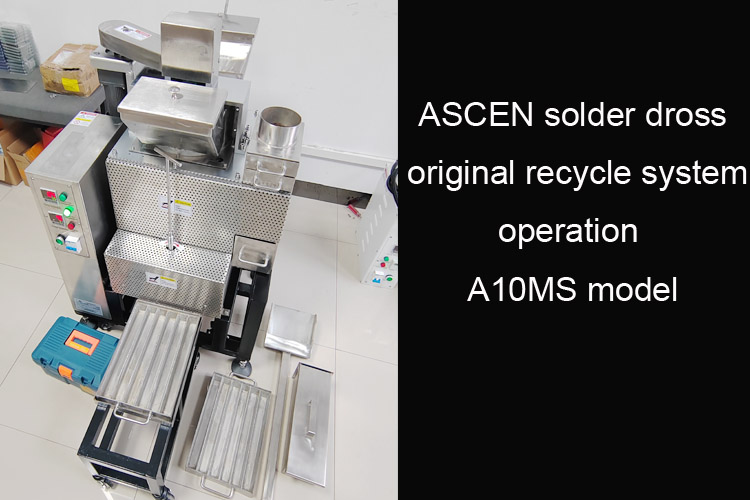

tin slag recovery machine solder dross waste extract system is an endeavor in reverting and recycling the oxides which occur during working of a Wave Soldering Machine in order to reduce production cost, create a greener environment and assist the quality process.Recycle,Reduce,Re-use is set to become as much an industry mantra as smaller,faster,cheaper, as issues such as energy and resource consumption and waste management are pushed to the fore.adhering to these new priorities can result in cost savings.By automating the solder dross recovery from their wave soldering process,a manufacturer can reduce de-drossing time by up to 80% and solder purchases by up to 50%.

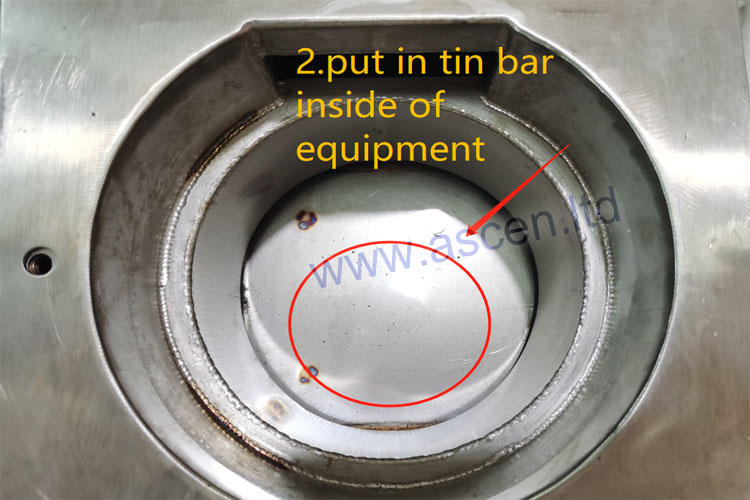

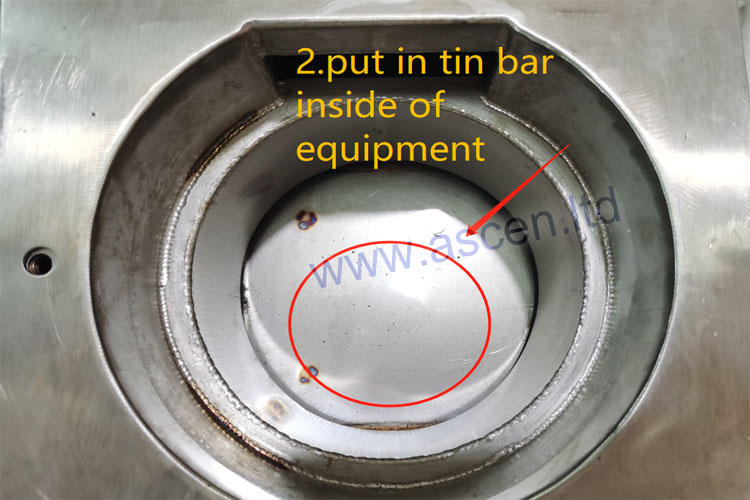

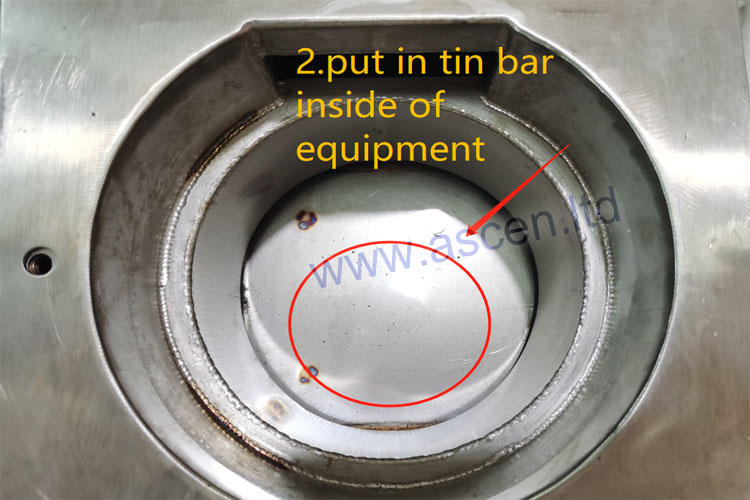

Activates the specific weight of the materials that have to be separated by solder dross waste extract system.before the first time use the tin slag recovery machine,we need disassembly the top device of solder recycling equipment and then put in 20kg of tin bar inside the solder recycling machine. And then reinstall the top device.when the solder dross recycling machine working,the tin slag separator will turns the tin bar into liquid tin.after the tin slag is filtered by the solder dross separation device process,the reusable alloy settles in the lower section of the pot while the dross floats on the surface.The reusable have identical characteristic to the present alloy captured in the solder pot.

The solder dross recovery equipment will automate output the solder dross ash to the junk box.at the meantime,store the separated tin in the material receiving box.Once the material receiving box is full,the tin slag recovery machine solder dross waste extract system will alarm and stop working until the operator come and release the tin.Once the operator open the discharge knob,the tin will flow to the bottom tin box,you need manual close the discharge knob if the tin box is full and wait the next release.after ten minute,the liquid tin in the tin box will curdle until became the tin bar.the solder dross recycling equipment finish the whole solder dross recycling and then the operator can take the tin bar to the wave soldering machine for reuse.

The accessories list as following:

1)2 pieces of tin box(use for replace when using)

2)2 pieces of junk box(use for replace when using)

3)1 pieces of screw rob(use for turn the discharge knob)

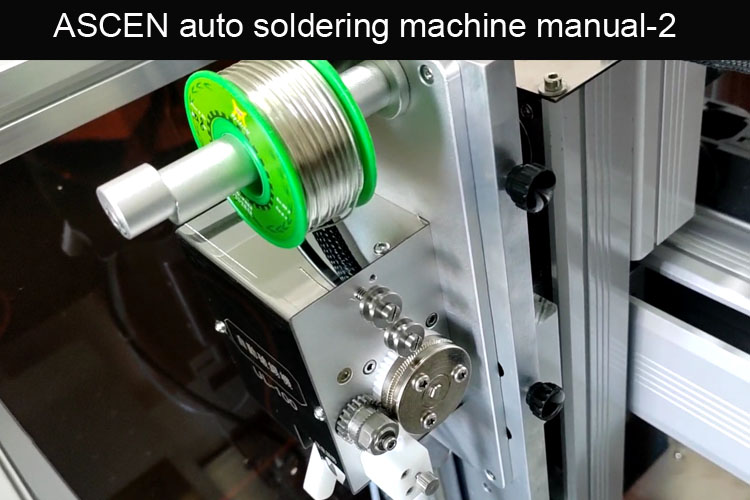

SMT tin slag recovery equipment systems video manual:

Step1:Disassembly the top device of solder recycling equipment and put in 20kg of tin bar inside the solder recycling machine.

Step 2: Reinstall the top device

Step 3: About how to use this ASCEN tin slag recycling equipment to separator your tin slag