Are you ready updated to Industry 4.0

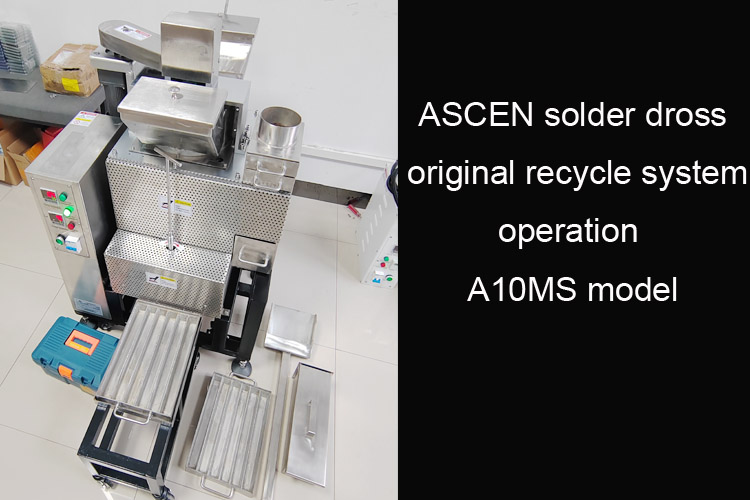

ASCEN solder dross recycling machine tin slag separator system

Solder recycling machine and solder dross separator operation

solder dross recycling machine tin slag recycle system manual

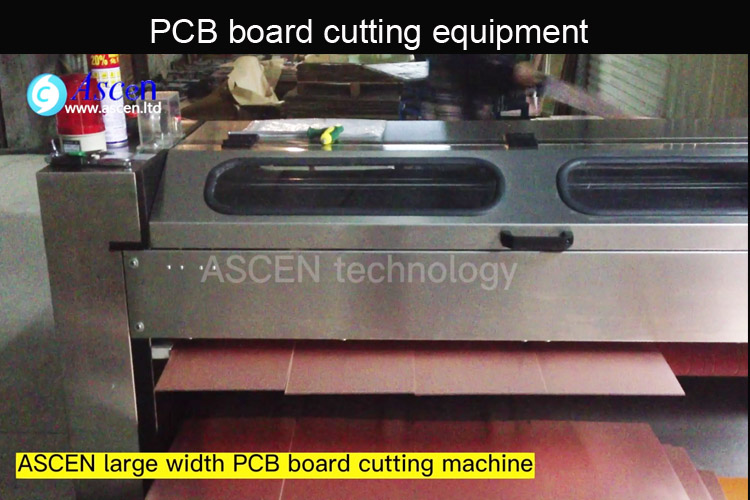

PCB board cutter equipment PCB material cutting machine

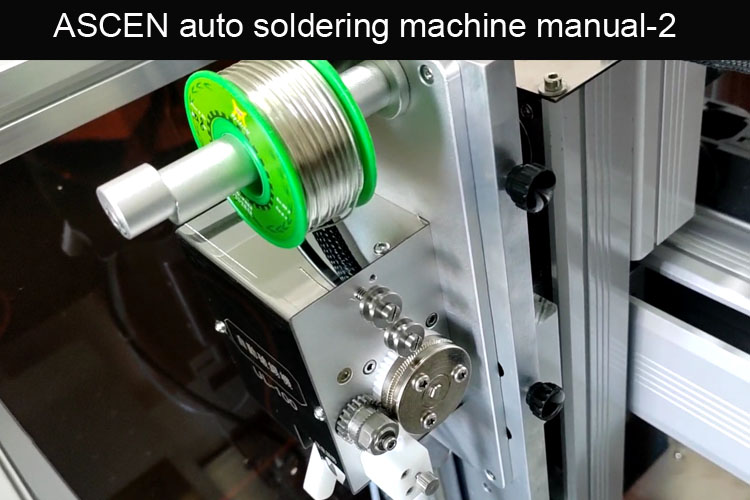

ASCEN PCB robotic soldering machine programming manual 3

ASCEN CNC Automatic Wave Soldering Machine manual 2 for PCB board

ASCEN PCB automatioc soldering robot machine manual 1

ASCEN aluminum profile/PVC tube cutting equipment

tin slag recovery machine solder dross waste extract system manual

Solder Dross separator Tin Waste Slag recycle equipment manual

Whether you'd like to get more info on what,why and how we do what we do, need help with what you're creating,would line to partner up or just say hi!

—--- We'd love to hear from you.

Note : Your information detail will not be published. Required fields are marked*